Updated: 10th October 2025

The Internet of Things (IoT) (opens new window) is transforming how we collect and use data from the physical world — and sensors are at the core of this revolution. Once simple measuring devices, IoT sensors have become intelligent tools that enable real-time monitoring, automation, and decision-making across every industry.

From tracking equipment performance in factories to optimizing energy use in smart buildings or maintaining product quality during transport, sensors are what make connected systems truly “smart.” Understanding the different types of IoT sensors and how they’re applied helps organizations design solutions that improve efficiency, safety, and innovation.

What are IoT Sensors?

IoT sensors are devices that detect and measure physical properties from their environment, then transmit this data to other connected systems via the internet. They form the foundation of IoT, acting as the eyes and ears that collect data from the physical world and convert it into actionable digital insights.

At their core, sensors work by detecting changes in environmental conditions—whether that's temperature shifts, movement, pressure variations, or chemical compositions. Once gathered, data flows through IoT devices to cloud platforms where it can be analyzed and used to trigger automated responses.

The Value of Real-Time Data Collection

The value of IoT sensors lies in their ability to provide real-time data continuously and remotely. This enables organizations to monitor assets, optimize operations, and respond to conditions as they happen. In industrial settings, this translates to predictive maintenance (opens new window) strategies that prevent equipment failures. In smart homes, it means automated climate control and enhanced security.

Modern IoT Sensor Capabilities

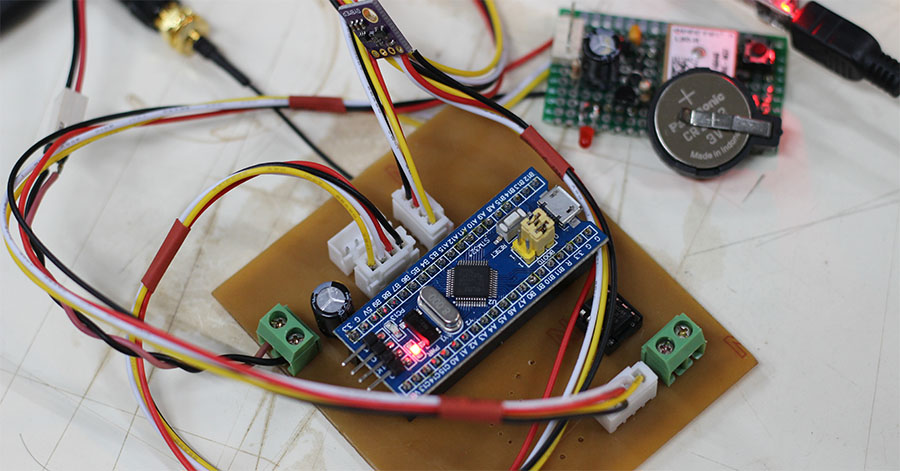

Modern IoT sensors range from tiny embedded chips in consumer electronics to robust industrial-grade devices designed for harsh environments. What unites them is their connectivity—the ability to transmit vital signs of systems and processes across networks, enabling smarter decision-making at scale.

Types of Sensors in IoT

The diversity of IoT applications demands various sensor types, each designed to measure specific physical phenomena. Understanding these different types of sensors helps organizations select the right technology for their use cases.

Temperature Sensors are among the most common in IoT deployments. These sensors monitor thermal conditions in everything from data centers to manufacturing floors. In industrial IoT (IIoT) settings, they help maintain optimal operating temperatures for machinery, while in smart homes they enable intelligent climate control systems.

Pressure Sensors measure force applied to a surface, making them critical in automotive, aerospace, and manufacturing industries. These sensors monitor hydraulic systems, detect leaks in pipelines, and ensure industrial processes maintain safe operating pressures.

Proximity Sensors detect the presence or absence of objects without physical contact. Using infrared, ultrasonic, or capacitive technologies, these devices are essential for automated assembly lines, parking systems, and retail inventory management.

Motion Sensors detect movement through various methods including infrared, microwave, and ultrasonic technologies. An infrared sensor detects changes in heat signatures, making it ideal for security systems and occupancy detection in smart buildings. These sensors help conserve energy by triggering systems only when spaces are occupied.

Gas Sensors monitor air quality by detecting specific gases or overall air composition. In industrial IoT contexts, they provide early warning of dangerous leaks. Smart home applications use them to detect carbon monoxide or natural gas, automatically alerting residents when hazardous levels are detected.

Humidity Sensors measure moisture content in the air, crucial for applications ranging from agricultural IoT to museum artifact preservation. These sensors help maintain optimal environmental conditions for sensitive equipment and materials.

Optical Sensors convert light into electronic signals and include photodetectors, fiber optic sensors, and image sensors. They enable machine vision systems in manufacturing, ambient light adjustment in smart homes, and quality control processes.

Level Sensors measure liquid or bulk solid amounts in containers, tanks, or silos. Industries rely on these sensors for inventory management, preventing overflows, and ensuring continuous supply in production processes.

Accelerometers & Gyroscopes detect orientation, tilt, vibration, and movement. These motion-sensing technologies are critical for predictive maintenance programs that monitor machinery vibration patterns to detect early signs of bearing failure or imbalance.

IoT Sensor Applications

The real power of IoT sensors becomes apparent when examining specific applications across different industries.

Predictive Maintenance in Manufacturing represents one of the most valuable applications of IIoT sensors. By combining vibration sensors, temperature sensors, and acoustic sensors on production equipment, manufacturers can detect anomalies that signal impending failures. This allows maintenance during planned downtime rather than responding to unexpected breakdowns.

Smart Homes and Buildings leverage multiple sensor types to create comfortable, efficient living spaces. Temperature and humidity sensors work with motion sensors to optimize climate control based on occupancy and environmental conditions. Gas sensors provide safety monitoring, while optical sensors automatically adjust lighting levels.

Healthcare Monitoring uses IoT sensors to track patient vital signs remotely. Wearable devices equipped with heart rate sensors, temperature sensors, and accelerometers continuously monitor patient health, alerting medical professionals to concerning changes. Pressure sensors in smart beds prevent bedsores by detecting prolonged pressure points.

Agriculture and Precision Farming relies on environmental monitoring through IoT sensors. Soil moisture sensors, combined with temperature and humidity sensors, help farmers optimize irrigation schedules. Level sensors in grain silos track inventory, while optical sensors on harvesting equipment assess crop quality in real time.

Supply Chain and Logistics uses IoT sensors to track shipments and maintain product quality during transport. Temperature sensors ensure cold chain integrity for pharmaceuticals and perishables, while accelerometers detect rough handling that might damage fragile goods.

Energy Management in industrial and commercial facilities uses power monitoring sensors alongside environmental sensors to optimize energy consumption. Motion sensors and proximity sensors ensure that lighting and HVAC systems operate only when needed, significantly reducing energy waste.

Integrating IoT Sensors with Davra

Collecting data from IoT sensors is only the first step—the real challenge lies in managing, analyzing, and acting on that information.

Davra's IoT platform (opens new window) provides a comprehensive solution for integrating diverse sensor types into cohesive, actionable systems.

The platform connects seamlessly with various IoT devices and sensors, regardless of manufacturer or communication protocol (opens new window).

Real-Time Data Processing and Analysis

Davra handles data ingestion from thousands of sensors simultaneously, normalizing and processing this information in real time. Edge computing capabilities allow for immediate analysis at the sensor level, reducing latency for time-critical applications.

Data visualization tools (opens new window) transform raw sensor readings into intuitive dashboards that provide at-a-glance insights into system health and performance. Customizable alerts notify relevant personnel when sensor readings exceed predetermined thresholds, enabling rapid response to emerging issues.

Predictive Maintenance and Machine Learning

For organizations implementing predictive maintenance (opens new window) strategies, Davra's platform applies machine learning algorithms to historical sensor data, identifying patterns that precede equipment failures.

This transforms reactive maintenance cultures into proactive ones, significantly reducing downtime and maintenance costs.

Security and Scalability

Security (opens new window) is built into every layer of the platform, ensuring that sensor data remains protected from collection through analysis and storage.

The platform's scalability means organizations can start with a focused sensor deployment and expand over time without replacing underlying infrastructure.

Enterprise System Integration

Integration with existing enterprise systems ensures that sensor-generated insights reach decision-makers in familiar formats. APIs (opens new window) enable custom integrations with ERP, SCADA, and other business systems, ensuring that IoT data enhances rather than complicates existing workflows.

Conclusion

IoT sensors are the building blocks of connected systems, turning raw environmental data into meaningful, actionable insights. By selecting the right combination of sensors and integrating them into intelligent platforms like Davra, organizations can move beyond simple monitoring to achieve true operational intelligence. Whether it’s improving efficiency, predicting maintenance needs, or enhancing safety, IoT sensors continue to drive the innovations that shape smarter, more connected industries.