Outcomes

- Aligned operations with GISTM controls.

- Improved the accuracy and accountability of tailings data.

- Increased client’s visibility of tailings data by 300%.

- Reduced insurance premiums and overall liability.

- Secured new clients that are driving strategic growth.

INTASOL Tailings is a service provider in the mining industry specializing in tailings management, headquartered in South Africa. They provide a range of services to mining companies including tailings deposition, hydro mining, and advisory services.

Tailings are the by-products left over from the mining process, often containing finely ground rock, water, and traces of the chemicals used in the extraction processes. They are stored in tailings storage facilities (TSFs), which typically consist of dams or embankments designed to contain the waste in a designated area. Millions of tons worth of tailings are deposited into the sites annually.

INTASOL Tailings regularly measures and reports on the status of the TSFs they manage using devices such as piezometers, drains, freeboard, etc., requiring workers to go onto the facility to take readings. Before partnering with Davra, the company was forced to rely on manual data collection involving error-prone pen and paper and countless, disconnected Excel spreadsheets.

The Risks of Tailings Managements

Tailings facilities are a significant risk. If a breach or failure occurs, it can cost the owner billions of dollars in damages, fines, and clean-up costs. As a result, clients are required to accept millions of dollars worth of insurance liability to have their facilities covered. Should one of their tailings fail and subsequently the operator's data is found to have been inaccurate, INTASOL Tailings would face fines and damage to its well-established reputation.

Manual data collection can lead to human error, lacks traceability and accountability, and allows data to be modified or fabricated. It can also result in long delays between when the data is collected and when it is finally reviewed.

This increases the risk of issues being identified late, or not at all, leading to embarrassment and reputational damage at best, or a major failure at a tailings facility at worst. While INTASOL Tailings has had no issues to date, they wanted to get out in front of this and reduce their risk as much as possible.

Finally, the industry has established the Global Industry Standard on Tailings Management (GISTM) which all companies must meet by August 2025. As a result, mining companies are imposing strict compliance requirements on service providers like INTASOL Tailings. This means that INTASOL Tailings must implement GISTM guidelines to stay competitive in the market.

A Hybrid Solution

INTASOL Tailings launched a strategic initiative to digitize its operations, seeking a solution to optimize reporting accuracy and traceability, enable GISTM compliance, and provide clients with peace of mind. Their vision was a centralized application for all operations and reporting, including HMS reporting, site inspections, and monthly inspections.

However, recognizing that not everything on a mine could be digitized, INTASOL Tailings sought a hybrid solution. Brink Loots, Operations Specialist at INTASOL Tailings, believes that effective tailings management requires “boots on the ground,” so one of their key requirements was an app allowing them to take measurements directly at the facility.

INTASOL Tailings chose Sentinel, Davra’s remote monitoring and tailings management solution developed in partnership with ESA (opens new window). They needed a solution they could believe in 100%, and Sentinel enabled them to digitize their tailings management, ensuring accurate, available, and traceable data.

According to Brink, “Davra listened. We never got to a point where they said, ‘No, this can’t be done’.”

Accuracy, Traceability, and Accountability

Sentinel’s accompanying mobile app enables INTASOL Tailings’s workers to record readings digitally while still getting boots on the ground. There is also the option to capture data remotely via IoT-connected sensors.

Each reading is geo-tagged, time-stamped, and stored in a secure database to ensure traceability. It then goes through a robust approval process, where a line manager reviews the data to ensure it has been captured, recorded, and interpreted correctly. The data is only made available to the client once it has been approved by three separate individuals, ensuring total accuracy, traceability, and accountability.

“Clients don’t have to wait until the end of the month to see what’s happening. They can log on and see a snapshot at any stage. What’s nice is that the measurements are geo-tagged on the site, so everyone can see where the measurements were taken and when.” - Brink Loots, Operations Specialist.

The cloud-based solution allows INTASOL Tailings to view and manage its operations from anywhere. It also greatly simplifies the reporting process, as Sentinel automatically generates reports using custom templates.

Brink expects Sentinel will prove popular with his clients, as they won’t have to wait until the end of the month to see what’s happening at their facilities. Instead, they can log on to Sentinel and get a snapshot of the facility at any time.

The traceable, geo-tagged data and robust approval process provide peace of mind that their facilities are as safe as possible. He anticipates that once rolled out, clients will log on to see their data several times per month, increasing data visibility by as much as 300%.

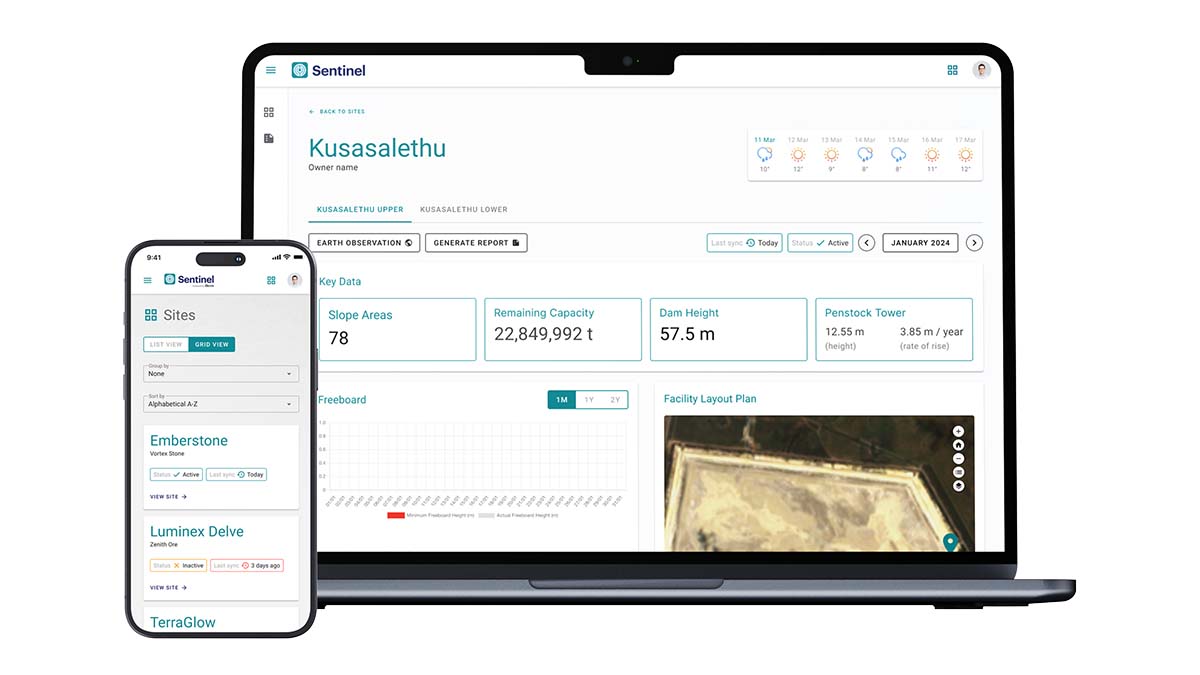

The Davra Sentinel application.

The Davra Sentinel application.

GISTM Compliance

Sentinel simplifies GISTM compliance and enables INTASOL Tailings to make data and information about its facilities accessible online. Not only can they now fulfill the needs of their clients, but they can also ensure alignment with international standards. This improves safety and sustainability in the mining industry while protecting INTASOL Tailings against fines and penalties for non-compliance.

This will also have a positive knock-on effect on insurance liability and premiums. By demonstrating to insurers that they are addressing GISTM requirements, clients foresee a reduction in their premiums.

Differentiation

INTASOL Tailings’s story is a perfect example of the benefits of digital transformation in the mining industry. With Davra, they were able to realise their vision of a centralized application for their operations, becoming industry leaders in the process. Sentinel has transformed their operations, simplifying compliance, improving data accuracy and traceability, and giving stakeholders peace of mind that their facilities are in good hands.

According to Brink, word is spreading that INTASOL Tailings has an impressive new system. “Sentinel is helping us grow strategically and sign on new clients because of the way we’re managing their facilities,” he explained.

Sentinel’s Earth Observation feature will further transform their understanding of what is happening at each facility. EO data such as ground displacement, soil moisture, and vegetation health combined with data on the ground provides a complete, 360-degree view of the tailings facilities.

Brink believes the EO features will be highly advantageous for their engineers. "It will absolutely be beneficial for them," he affirmed. "Without a doubt."

Conclusion

INTASOL Tailings has significantly enhanced its tailings management operations by implementing Sentinel, Davra's remote monitoring and management solution. This digital transformation has brought about numerous benefits, including improved data accuracy, traceability, and accountability, as well as simplified compliance with GISTM.

The hybrid approach, combining digital tools with boots on the ground, has ensured that they can continue to deliver a safe, reliable, and transparent service for their clients. As a result, INTASOL Tailings has impacted its insurance premiums and liability, strengthened client relationships, and provided peace of mind to all stakeholders. They plan to leverage Sentinel’s capabilities to further streamline its operations, and attract new clients with its superior facility management.

About Sentinel

Davra Sentinel is a remote monitoring application for tailings storage facilities (TSF). Developed in partnership with ESA (opens new window), Sentinel combines EO data with real-time telemetry from ground sensors, providing continuous oversight and improving the safety, efficiency, and compliance of tailings management.

For more information, visit davra.com/sentinel.