The Industrial Internet of Things (IIoT) is revolutionising safety standards across various sectors by seamlessly connecting equipment, people, and processes. This transformative technology is enhancing worker safety in industries such as manufacturing, energy, transport, oil and gas, and mining. By leveraging an array of innovative technologies, including ground sensors, wearables, geofencing, and earth observation, IIoT ensures the safety of operations, infrastructure, and the environment.

With real-time monitoring capabilities, even in the most remote locations, IoT allows for the continuous analysis of telemetry data. IoT solutions can quickly detect potential hazards and send automated alerts to key stakeholders, enabling swift resolution. Geofencing technology creates virtual boundaries to protect workers, while AI offers powerful predictive capabilities to foresee and mitigate risks before they become critical issues.

This article will explore IoT safety use cases and show how IoT is creating safer industrial working environments.

Remote monitoring & alerts

One of the most significant advantages of IoT in industrial environments is the ability to monitor remote locations in real time. IoT devices equipped with sensors can continuously track variables such as temperature, humidity, gas levels, and machinery performance. Low power wide area network (LPWAN) IoT technologies like LoRa, NB-IoT, LTE-M, and Sigfox enable long-range communication even with small, battery-powered devices.

This constant flow of IoT data allows for the immediate detection of anomalies or hazardous conditions. For example, if a sensor detects a gas leak, an alert can be sent instantly to both the worker and the control room, enabling swift action to mitigate the danger.

Remote monitoring capabilities also extend to Earth Observation (EO) satellite imaging. EO can provide oversight of key infrastructure, including mines, roads, railways, and oil and gas pipelines, as well as natural hazards. Satellite image processing can reveal ground movement, soil moisture levels, and changes in vegetation health, all of which can serve as leading indicators of potential disasters.

Davra Sentinel is a remote monitoring application for safe, efficient, and compliant tailings management. Developed in partnership with ESA, Sentinel combines state of the art Earth Observation with IoT sensor data. This combination gives engineers an unparalleled view of their tailings facilities.

Lone Worker Protection

Wearable devices such as smartwatches, badges, and hardhats (opens new window) equipped with IoT sensors, monitor a worker’s vital signs, location, and movements. These smart devices can detect signs of fatigue, distress, and other unwanted events, and automatically send alerts, shut down machinery, or contact the emergency services.

Environmental sensors further enhance safety by detecting hazards like gas leaks, temperature extremes, or unsafe air quality, providing instant alerts to both the worker and the safety team.

GPS trackers also track the precise location of lone workers, so if something does go wrong the emergency services can find them quickly. Next we'll talk about geo-fencing technology, which protects lone-workers by monitoring when they enter or leave a designated zone.

Geofencing

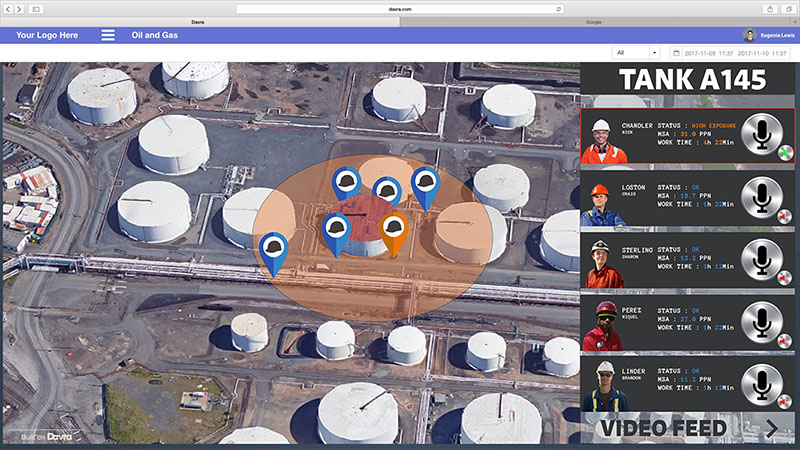

Geofencing technology protects workers from hazardous environments by acting as a digital shield. Geofencing creates virtual boundaries around dangerous areas, such as gas storage facilities, high-voltage wiring, rail lines, and other high-risk zones, ensuring that both personnel and equipment operate within safe limits.

Geofencing uses GPS, RFID, Bluetooth, Wi-Fi, and cellular data to create virtual perimeters around specific locations. Organisations can customize boundaries to fit the needs of any industrial site. Once established, the geofence monitors the positions of workers and equipment within its defined area. If a person or piece of equipment breaches these virtual boundaries, the system can trigger various actions.

Workers within the designated zone can communicate with each other while operators monitor live video feeds, air quality, and exposure limits to protect workers. Alerts can also be raised when unauthorised personnel enter restricted zones, ensuring only trained individuals are present in hazardous areas.

Case Study: SAFETRX

Davra customer SAFETRX (opens new window) is a prime example of how IoT technology can enhance workplace safety, particularly for lone workers. The smartwatch and accompanying monitoring platform track the location and safety of workers in real time, providing a robust solution for industries where employees often work alone or in isolated areas.

Features of SAFETRX

- Real-Time Location Tracking: GPS technology provides real-time location tracking, ensuring that the exact position of it’s wearer is always known.

- Smart alert monitoring: The wearable features a range of biometric, gesture, push button, and positional alarms.

- Automated Check-Ins and Alerts: SAFETRX can be programmed for automated check-ins at regular intervals. If a worker fails to check in, the app sends an alert to the designated contact, prompting a safety check.

- Emergency Response: In case of an emergency, workers can activate an SOS alert through the app. This alert immediately notifies supervisors and emergency contacts, providing the worker’s location and critical details about the situation.

- Environmental Monitoring: The app can integrate with various sensors to monitor environmental conditions such as air quality, temperature, and noise levels, ensuring that workers are not exposed to harmful conditions.

Impact of SAFETRX

SAFETRX has significantly improved safety protocols for companies with lone workers. By leveraging real-time IoT data and automated alerts, the solution ensures that workers are never truly alone, even in the most isolated environments. The integration of environmental monitoring further enhances safety by preventing exposure to hazardous conditions. Companies using SAFETRX have reported reduced response times in emergencies, improved compliance with safety regulations, and greater peace of mind for both workers and management.

Join our Mailing List

Join thousands of professionals and get IoT tips to help you transform your business.

Critical Control Management

Critical control management is a systematic approach to managing risks by ensuring that critical controls are in place and effective. IoT technology significantly enhances critical control management by continuously monitoring and verifying critical controls.

For instance, RFID tags on personal protective equipment (PPE) ensure that workers are properly equipped, while air quality monitors keep track of environmental conditions. Additionally, computer vision technology can be used to detect unsafe behaviours or conditions in real-time.

Risk owners can establish rules within these IoT systems that raise timely alerts when issues surface, helping to prevent problems before they escalate. If performance falls below a predefined threshold, it should trigger an appropriate response, ranging from an investigation to an immediate halt of the relevant work processes. This proactive approach ensures that critical controls remain effective, thereby safeguarding worker safety and operational integrity.

Predictive Maintenance

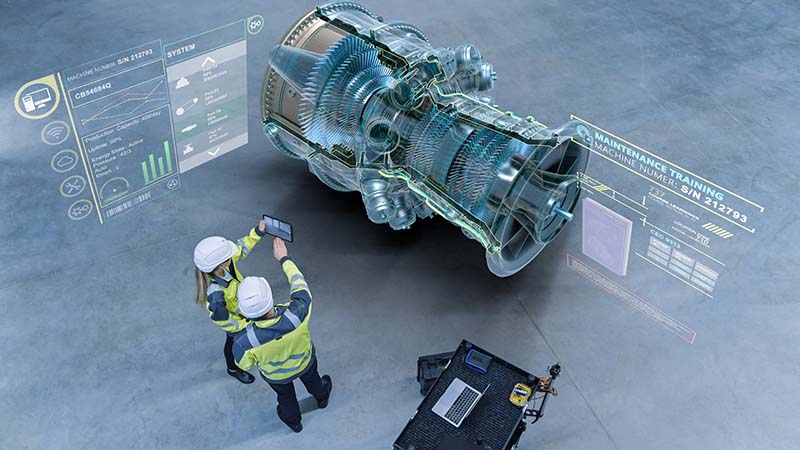

IoT technology enables the prediction of equipment maintenance (opens new window) needs before they become problematic. By analysing telemetry data from connected devices installed on equipment, AI and machine learning can be employed to scrutinise historical data, creating powerful predictions of future behaviour.

When trends in the data indicate that a piece of equipment is beginning to fail, protective measures can be initiated. These measures can include automatically scheduling maintenance, shutting down at-risk equipment, or issuing alerts to workers within a geofenced area. This proactive approach not only prevents equipment failures but also enhances overall operational efficiency and safety, ensuring that maintenance is performed before a minor issue escalates into a major problem.

Conclusion

The Industrial Internet of Things (IIoT) is revolutionising safety in various sectors by integrating equipment, people, and processes. This technology is crucial for enhancing worker safety in industries such as manufacturing, energy, transportation, oil and gas, and mining. Through real-time monitoring, geofencing, wearable devices, and predictive maintenance, IIoT is setting new safety standards.

To discover how IoT can revolutionise safety in your industry, contact Davra today. Together we can build innovative solutions that will transform your workplace.