Industrial equipment failures can cost organizations millions annually through unplanned downtime, emergency repairs, and lost productivity. Predictive maintenance for industrial equipment offers a transformative solution, enabling organizations to prevent failures before they occur and optimize maintenance operations through data-driven insights.

In this post, we’ll explore the essential technologies, strategies, and benefits of predictive maintenance for industrial operations. We’ll also examine different methods, software options, and implementation strategies to help organizations determine the best approach for their needs.

Whether you’re retrofitting existing equipment or designing new connected products, this guide will give you a clear understanding of how predictive maintenance for industrial equipment works and how to make it work for you.

What is Predictive Maintenance

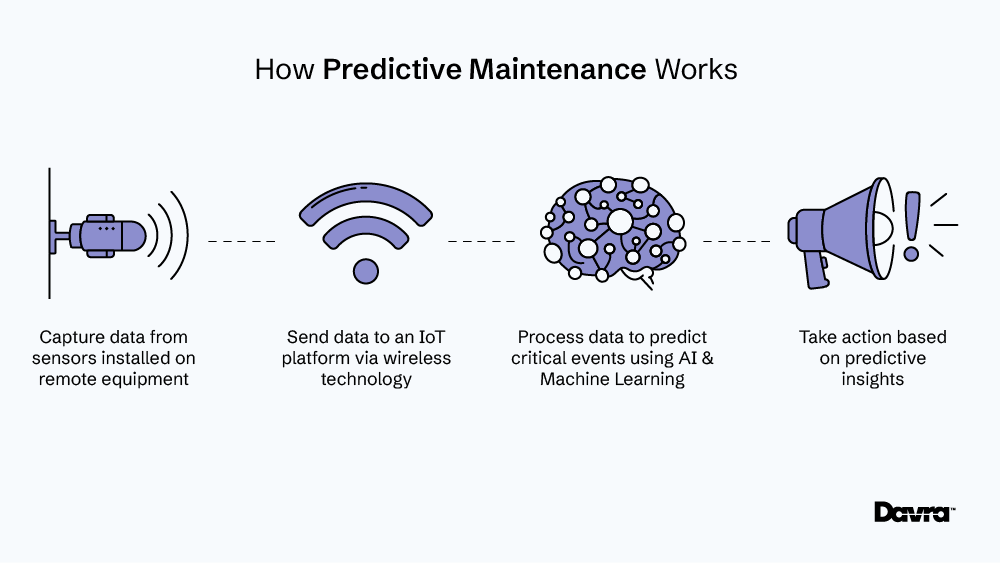

Predictive maintenance (PdM) (opens new window) is a data-driven strategy that leverages sensors, IoT technology (opens new window), and AI-powered analytics to monitor equipment in real time and predict failures before they happen. Unlike reactive maintenance, which waits for equipment to break down, or preventive maintenance, which follows a fixed schedule, predictive maintenance allows organizations to perform maintenance only when it’s actually needed.

This approach represents the most advanced stage of modern maintenance practices. Organizations typically evolve through three key phases:

- Condition monitoring (opens new window) – collecting real-time data from equipment.

- Condition-based maintenance – taking action when certain thresholds are met.

- Predictive maintenance (opens new window) – using machine learning to forecast failures before they occur.

As organizations build up historical data and improve their analytical capabilities, they can move from simple reactive alerts to fully proactive maintenance models. This shift enables smarter scheduling, reduced downtime, and more efficient management of spare parts and resources.

Predictive maintenance relies on a sophisticated technology ecosystem. IoT platforms (opens new window) or other analytics platforms continuously process both real-time and historical data to detect patterns and trends that may be invisible to human operators. These insights are delivered through intuitive dashboards (opens new window), real-time alerts, and automated reports—empowering teams to make informed, timely decisions.

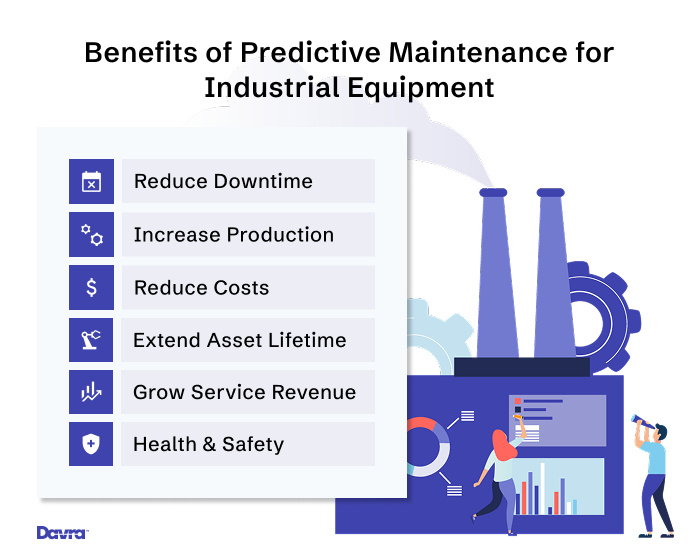

Benefits of Predictive Maintenance for Industrial Equipment

Predictive maintenance for industrial equipment delivers strong ROI across operations, with organizations achieving cost recovery in under a year while gaining major benefits in efficiency, asset management, and safety.

Reduced Downtime

Reducing unplanned downtime by identifying potential failures weeks or months in advance, predictive maintenance allows scheduled repairs during planned windows instead of costly emergency shutdowns. This maximizes equipment availability, production throughput, and overall equipment effectiveness (OEE) by synchronizing maintenance with production schedules rather than forcing interruptions.

Cost Savings

Equipment breakdowns can be extremely costly, both to replace the equipment and parts as well as the loss of productivity. According to the latest research from IoT Analytics (opens new window), the median cost of unplanned downtime across 11 industries was approximately $125,000 per hour.

Predictive maintenance reduces labor, inventory, and downtime costs, with organizations typically recovering investment in under a year. By prioritizing maintenance based on equipment condition rather than fixed schedules, it prevents costly failures and minimizes emergency procurement needs.

Asset Lifetime Extension

Predictive maintenance continuously monitors equipment to perform maintenance at optimal times, extending asset lifecycles and preventing costly failures. By identifying performance degradation early, this approach enables targeted interventions that maintain peak performance while maximizing equipment lifespan.

Aftermarket Service Revenue

For OEMs offering smart, connected products, aftermarket service offerings are a key driver of revenue growth. Predictive maintenance, in particular, stands out as a high-value service that differentiates the OEM’s solution from third-party aftermarket providers. By helping customers reduce downtime and lower long-term maintenance costs, it boosts operational efficiency while deepening the vendor-customer relationship. This not only improves customer retention but also cultivates long-term brand loyalty.

Predictive Maintenance Technology for Industrial Equipment

Successful predictive maintenance implementation relies on three core technology components working together: advanced sensor networks for data collection, IoT and communication technologies for connectivity, and AI/ML algorithms for intelligent analysis.

Sensors

The foundation of any predictive maintenance system lies in its sensor technology, which converts physical equipment parameters into measurable data that can be analyzed for condition assessment.

Vibration Sensors

Vibration sensors are the most common condition monitoring devices, particularly effective for rotating equipment like motors, pumps, and turbines. They detect bearing wear, misalignment, imbalance, and other mechanical issues.

Other Sensor Types

Effective predictive maintenance often requires multiple sensor types to provide a complete view of equipment health, depending on the specific equipment and application. Other common sensor types include temperature, visual, chemical, and ultrasonic sensors.

Temperature sensors monitor thermal conditions that can indicate electrical problems, lubrication issues, or excessive friction. Chemical sensors, such as those used in oil analysis, reveal signs of wear, contamination, or lubricant degradation, while gas sensors detect leaks or combustion byproducts in fuel or chemical systems. Ultrasonic sensors pick up high-frequency sounds from issues like air leaks, electrical discharge, or early-stage bearing faults—often before they become visible.

IoT & Communication Technologies

Wireless connectivity has revolutionised condition monitoring implementation (opens new window) by eliminating the need for extensive wiring installations and enabling monitoring of previously inaccessible equipment locations. Modern communication technologies provide the infrastructure needed to connect distributed industrial equipment and transmit critical monitoring data to centralized analytics platforms.

Internet of Things (IoT) platforms like Davra (opens new window) seamlessly connect industrial equipment across different locations, protocols, and hardware technology. Various connectivity options are available depending on specific application requirements, including cellular networks for remote locations, Wi-Fi for high-bandwidth applications, satellite for extremely remote locations (e.g., mines), and low-power wide-area networks (LPWAN) for battery-powered sensors that need to operate for years without maintenance.

Edge computing capabilities allow local data processing and buffering, ensuring critical information is captured even when connectivity is intermittent.

Machine Learning and AI for Predictive Maintenance

Machine Learning (ML), Artificial Intelligence, and other advanced approaches analyze collected data to establish key patterns and relationships between variables. These systems detect statistical anomalies and deviations that indicate potential issues, learning continuously to improve prediction accuracy over time.

Advanced statistical approaches and machine learning models process vast amounts of historical and real-time data to identify complex patterns that indicate impending failures. These algorithms and models can be updated in real time, helping their predictions to become more refined over time.

Anomaly Detection and Remaining Useful Life are currently the most common models used for predictive maintenance.

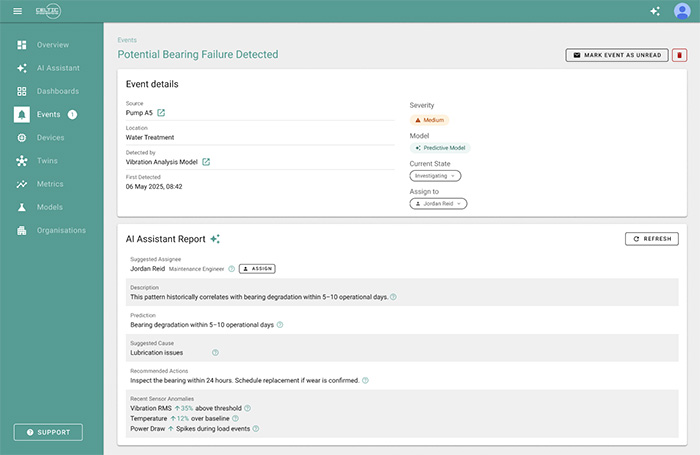

Predictive Maintenance Software for Industrial Equipment

A custom predictive maintenance solution build on the Davra platform.

A custom predictive maintenance solution build on the Davra platform.

Organizations face a critical decision when implementing predictive maintenance software: choosing between building a custom solution or buying something “off-the-shelf”. This is the classic Build vs Buy debate. Each approach offers distinct advantages depending on organizational requirements, technical capabilities, and operational scope.

Off-the-Shelf Predictive Maintenance Software

Pre-built predictive maintenance solutions are quick to deploy, lower cost, and lower complexity. However, they offer limited customization options, may present integration and security challenges, and don’t allow customers to create a unique, differentiated product that provides a competitive edge in the market.

Off-the-shelf solutions are best suited for facility managers who need to retrofit predictive maintenance capabilities to existing or older equipment with standardized monitoring requirements.

Examples of predictive maintenance solutions include:

1. i-care

i-care delivers real-time condition monitoring and AI-driven analytics to detect early equipment faults, helping industries prevent unplanned downtime and reduce maintenance costs.

2. MaintMaster

MaintMaster provides a flexible CMMS with predictive capabilities, enabling tailored maintenance workflows and seamless integration with sensor data for early fault detection.

3. ABB

ABB's Ability™ platform leverages machine learning and sensor data to predict equipment failures, optimize maintenance schedules, and improve overall asset performance.

4. Rockwell Automation

Rockwell's FactoryTalk® Analytics uses IoT data and AI models to deliver predictive insights that help extend asset life and avoid unplanned shutdowns.

5. Augury

Augury's Machine Health platform combines AI with vibration and ultrasonic sensors to predict failures and provide actionable maintenance recommendations.

Custom Predictive Maintenance Solutions

Custom predictive maintenance solutions provide maximum flexibility and integration capabilities for complex industrial environments. A custom solution supports any sensor type and configuration, accommodating diverse monitoring requirements across different equipment types and manufacturers.

Custom solutions are best suited for original equipment manufacturers (OEMs) who need remote monitoring capabilities, extensive customization options, and the ability to offer predictive maintenance as a value-added service (opens new window) to their customers.

Organizations considering a custom predictive maintenance solution have two options: buy-and-build (opens new window) on an IoT platform, or custom-build from scratch. Davra helps OEMs connect their equipment and create unique, differentiating predictive maintenance solutions with a buy-and-build approach. If this is you, get in touch (opens new window) with us today to find out how we can help your organization.

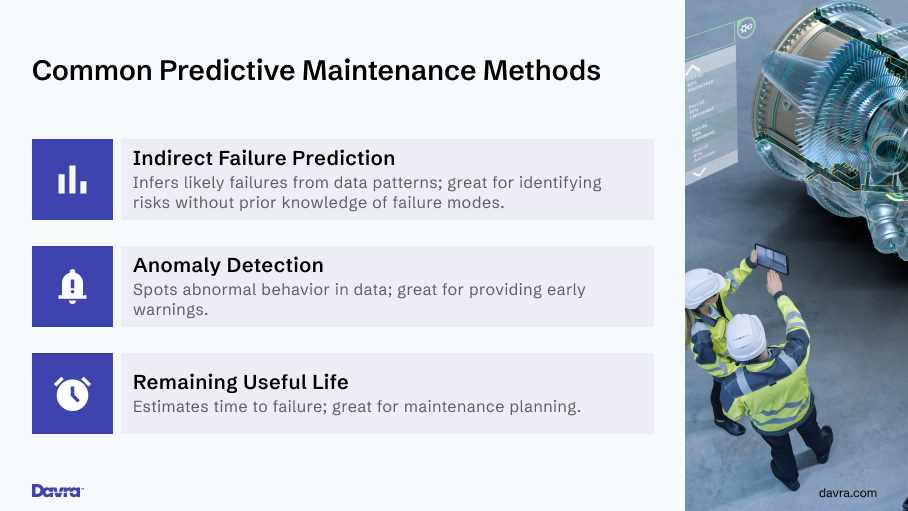

Common Predictive Maintenance Methods

There are various types of predictive maintenance methods, employing different analytical methodologies. Some approaches focus on detecting early warning signs, while others estimate how long equipment can continue operating before failure. Below we’ll look at three different methods: indirect failure prediction, anomaly detection, and remaining useful life.

Indirect Failure Prediction

Indirect failure prediction is a predictive maintenance strategy that generates an Asset Health Score—a numerical value representing the current and projected condition of an asset. This score reflects overall performance trends, identifies potential degradation, and estimates how close the equipment is to the end of its life cycle.

The Asset Health Score is calculated using a combination of factors, including sensor data, asset age, usage patterns, environmental conditions, and historical performance. This approach primarily relies on general data analysis techniques but can also incorporate supervised learning methods when labeled failure history is available.

Because it leverages widely available data and does not require complex machine learning pipelines, this method is particularly well-suited for organizations that lack the resources to develop and maintain advanced predictive models.

Anomaly Detection

Anomaly Detection (AD) is a predictive maintenance technique that identifies unusual patterns in machine data using statistical analysis and ML algorithms. AD is ideal for providing early warnings, helping teams catch issues before they cause equipment failure.

One AD methodology, known as Mahalanobis distance, measures how far various metrics deviate from “normal behavior” across multiple metrics. By analyzing historical data to understand what “normal” looks like, it can detect even subtle anomalies in the data. This method is great for achieving quick results, as it works out-of-the-box with minimal setup and no need for machine learning models or user input.

Remaining Useful Life

Remaining Useful Life (RUL) is a predictive maintenance technique that estimates how much time or usage remains before a machine or component is likely to fail.

The model works by training a supervised machine learning algorithm on past failure data. This model then identifies trends and patterns in real-time data to predict when a failure is likely to occur, providing a time estimate to that event.

RUL is great for proactive maintenance planning—allowing teams to schedule repairs, order parts in advance, and replace critical components at the most convenient time, minimizing downtime and disruption to operations.

Conclusion

Predictive maintenance represents a fundamental shift from reactive maintenance approaches to proactive, data-driven asset management strategies. By tracking equipment health via wireless sensorss, IoT connectivity, and AI, organizations see significant improvements in operational efficiency, maintenance planning, and overall equipment reliability.

If you are thinking about implementing predictive maintenance for your equipment, Davra can help. Get in touch with us today and learn how we can help deliver condition monitoring and predictive maintenance solutions for your industrial equipment with Davra’s AI-powered IoT Platform.