Condition monitoring (opens new window) has become a cornerstone of modern industrial operations, enabling organisations to shift from reactive maintenance to smarter strategies like condition-based maintenance and predictive maintenance (opens new window).

Thanks to ever-improving IoT technologies, implementing condition monitoring is now more accessible than ever. IoT platforms such as Davra (opens new window) provide all the tools to connect and continuously monitor industrial equipment, whether it resides on a factory floor, or in the remotest parts of the world.

In this article, we'll walk you through the complete end-to-end steps of how to implement condition monitoring of industrial equipment on the Davra Platform (opens new window)—from initial sensor installation to advanced custom application deployment.

What is Condition Monitoring

Condition monitoring is a strategy whereby equipment health is continuously tracked through real-time data collection and analysis. This proactive approach enables early detection of potential failures, optimising maintenance schedules and reducing costly downtime.

Condition monitoring is an essential first step in implementing advanced maintenance strategies such as condition-based maintenance (CbM) or predictive maintenance (PdM).

In a recent report (opens new window), the global smart maintenance market (including CbM and PdM) was valued at $29.3 billion in 2022, and is expected to reach $46.3 billion by 2028.

As such, equipment manufacturers looking to maximize the benefits of CbM and PdM for their business should look to implement condition monitoring with flexibility and scalability in mind.

For a deeper understanding of the fundamentals of condition monitoring, see our comprehensive guide: What is Condition Monitoring (opens new window).

How to Implement Condition Monitoring on the Davra Platform

As condition monitoring establishes the necessary data and infrastructure for more advanced IoT use cases, it is often one of the first things implemented by Davra customers.

Below, we'll show you how to implement condition monitoring on the Davra Platform in six basic steps.

Step 1: Install IoT Sensors

The implementation process begins by installing IoT sensors (opens new window) on the equipment to be monitored.

The sensor selection and installation approach depends heavily on your specific environment and requirements.

Wired vs. Wireless Considerations

Wired sensors offer reliable connectivity and continuous power but require physical infrastructure. Wireless sensors enable remote monitoring, but require careful consideration of communication technologies, power requirements, and environmental factors.

Environmental Factors

Consider your equipment's operating environment carefully. Remote locations may lack WiFi access, requiring cellular or satellite connectivity. Harsh industrial conditions demand ruggedised sensors with appropriate IP ratings for dust and moisture protection.

Communication Technologies

Different applications require different connectivity solutions:

- Bluetooth Low Energy (BLE): Short-range, low-power applications

- WiFi: High-bandwidth, infrastructure-dependent solutions

- Cellular: Wide-area coverage with ongoing data costs

- LPWAN (LoRaWAN, NB-IoT): Long-range, low-power for distributed assets

- Satellite: Remote locations without terrestrial coverage

Power and Processing Considerations

Battery-powered sensors require careful energy management, influencing sampling rates and transmission frequency. Edge processing capabilities can reduce data transmission requirements and enable local decision-making, while Cloud processing offers more computational power for complex analytics.

If you're struggling with hardware or technology decisions, speak to one of Davra’s experts (opens new window). We can advise you on which technologies may be the right fit for your specific application requirements.

Step 2: Connect to the Davra Platform

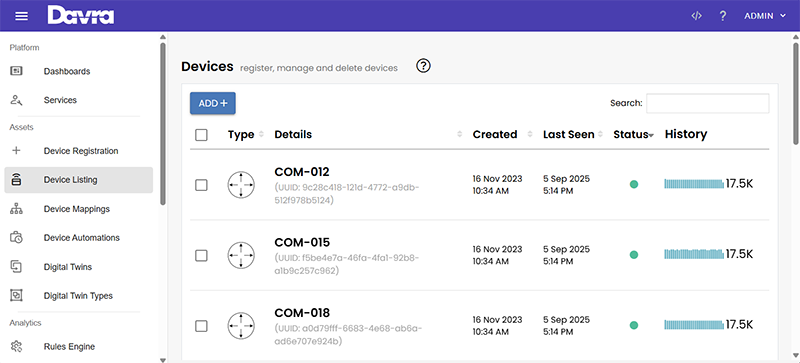

Once sensors are installed, they must be configured to communicate with the Davra Platform through appropriate wireless or wired connections. This process involves device provisioning (opens new window), network configuration, and security credential setup to ensure reliable, secure data transmission.

However, once a device type has been configured, adding additional devices of the same type becomes straightforward and can often be automated. The platform streamlines the deployment of multiple sensors by reusing established device profiles and network configurations, significantly reducing the time and effort required for large-scale IoT implementations.

Device Provisioning

The Davra Platform simplifies connectivity through comprehensive device management capabilities, including a comprehensive dashboard with real-time data, shown below. The platform supports all modern communication protocols and provides automated device provisioning features that streamline the onboarding process.

Device Listing

Device Listing

Network Configuration

Use specialised tools to configure network settings, including IP addresses, gateway connections, and communication protocols. The Davra Platform's edge gateway solutions aggregate data from multiple sensors locally before transmitting to the cloud, optimising bandwidth usage and ensuring data integrity.

Security Setup

Guided user interfaces are provided to implement comprehensive authentication and encryption protocols to protect your industrial data. Davra provides enterprise-grade security features including device certificates, encrypted communications, and role-based access controls.

For more on this topic, see https://developer.davra.com/devices (opens new window).

Step 3: Collect Data

With connectivity established, the system begins continuous data collection, storing measurements in the platform's database for analysis and trending. Data collection parameters such as sampling rates, measurement intervals, and data retention policies will depend on the specific equipment characteristics and monitoring objectives.

Configuring Collection Parameters

Set appropriate sampling rates based on the phenomena you're monitoring. For example, high-frequency vibration analysis requires faster sampling than temperature monitoring. Configure measurement intervals to balance data granularity with storage requirements.

Data Storage and Management

The Davra Platform excels in data collection with its high-performance time-series database optimised for industrial IoT applications. The platform can handle massive volumes of sensor data while maintaining fast query performance for real-time analytics and historical trend analysis.

Retention Policies

Configure data retention policies to preserve critical information while managing storage costs effectively. Raw high-frequency data might be stored short-term while aggregated trends are retained longer for historical analysis.

Step 4: Set up Automated Alerts

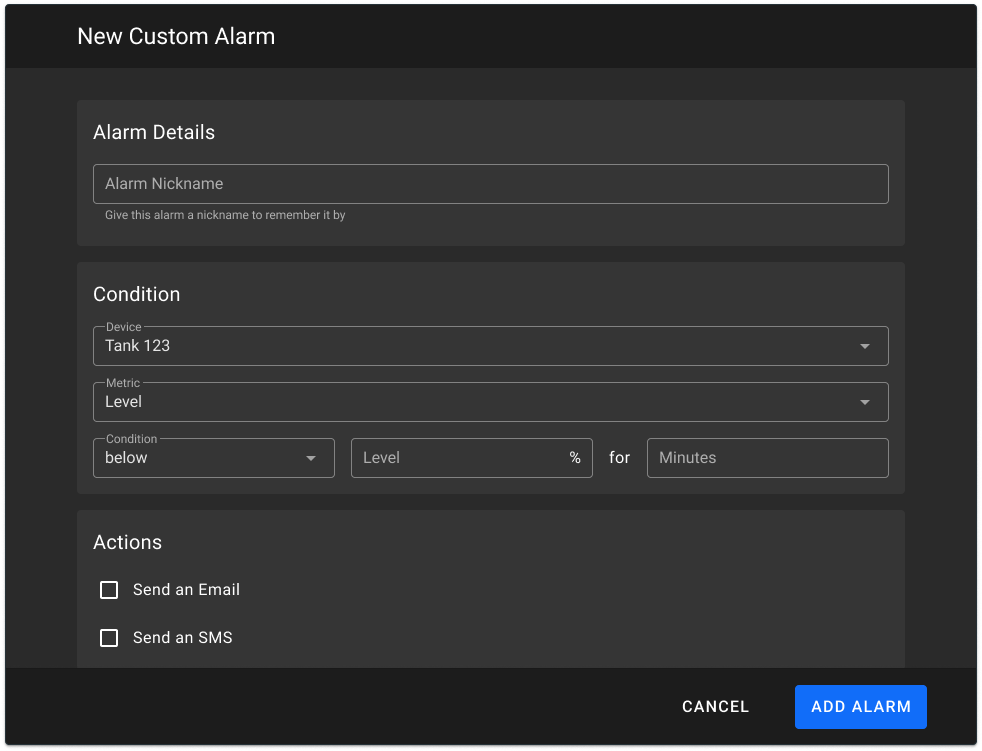

Custom alarm UI concept

Custom alarm UI concept

Automated alerting transforms raw sensor data into actionable intelligence by notifying the relevant teams when equipment conditions exceed normal operating parameters.

Alert Rules

Using the Davra Platform’s point-and-click Rules Engine, configure alert rules based on threshold values, trend analysis, and complex conditional logic. Rules can combine multiple sensor inputs to detect specific failure modes or operating conditions.

Alert Triggers

Set up trigger conditions including:

- Simple threshold crossing (temperature > 80°C)

- Rate of change detection (vibration increasing rapidly)

- Pattern recognition (unusual frequency signatures)

- Complex multi-parameter conditions

Alert Actions

Configure response actions when alerts trigger:

- SMS/Email Notifications: Immediate alerts to maintenance personnel

- API Calls: Integration with work order systems or maintenance management software

- Dashboard Indicators: Visual alerts on monitoring displays

- Automated Responses: Trigger control systems or safety shutdowns

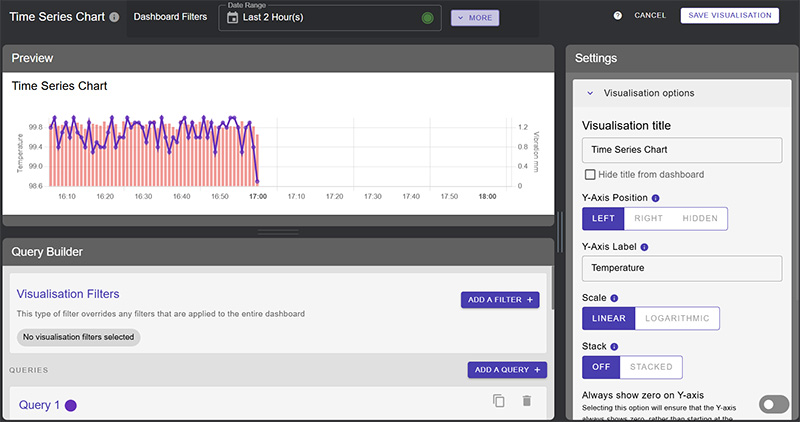

Step 5: Create a Dashboard

Dashboard configuration

Dashboard configuration

Effective condition monitoring requires an intuitive data presentation that enables users to quickly assess equipment status and identify developing issues.

Well-designed dashboards present information at multiple levels, from high-level facility overviews to detailed equipment-specific displays, enabling users to drill down from general status information to specific diagnostic data as needed.

Dashboard Creation with Davra

The Davra Platform offers powerful visualisation capabilities through its intuitive Dashboard Builder (opens new window), shown in the image above. Users can create sophisticated dashboards without coding, incorporating various chart types, alarm indicators, and KPI widgets.

Dashboards and charts display real-time measurements, trend charts, alarm status, and equipment hierarchy information, with drag-and-drop functionality and flexible layout options that enable fast deployment and easy modification as monitoring requirements evolve.

For more on this topic, see https://developer.davra.com/enable/dashboards (opens new window).

Step 6: Deploy a Custom Application

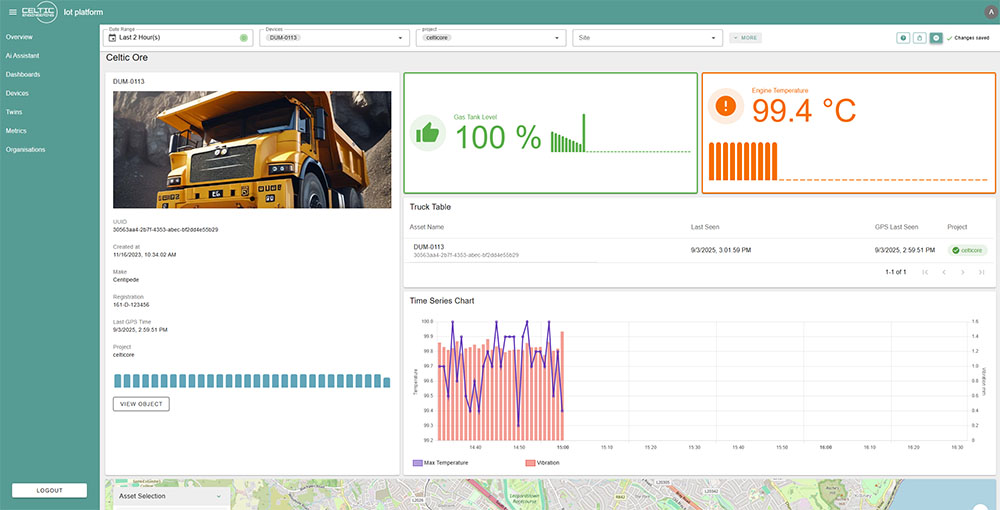

Custom application with embedded dashboard

Custom application with embedded dashboard

Finally, once data is flowing into the Davra Platform, visualised in your dashboards, adhering to the rules you’ve set up to monitor important events, it's time to enhance it. The Davra Platform supports custom application development through APIs and software development kits.

These custom applications can integrate condition monitoring data with existing enterprise systems, provide specialised analytics capabilities, and deliver white-labeled solutions that match organisational branding requirements.

Advanced Integration Capabilities

Custom applications enable advanced features such as:

- Automated work order generation

- Integration with maintenance management systems (CMMS)

- Specialised reporting capabilities supporting specific organisational workflows

- Custom analytics and machine learning implementations

Davra Platform Development Tools

Use the Davra Platform’s comprehensive APIs and development tools to rapidly build custom applications. Take advantage of the platform’s open architecture to integrate your existing best-in-class tools and systems, preserving your investments while extending capabilities.

Access our APIs and dedicated Developer Portal (opens new window) to streamline your development process. Achieve elite DevOps performance measured by industry-standard DORA metrics—deploy more frequently, shorten lead times, minimise change failure rates, and recover quickly.

Leverage the platform’s white-label capabilities to deploy condition monitoring solutions under your own branding. Build a unified ecosystem that combines Davra’s robust foundation with your specialist tools.

Development Environment

Use the Davra Platform’s development environment to quickly build custom dashboard applications without deep programming expertise. Accelerate time-to-value for your condition monitoring projects while maintaining enterprise-grade functionality.

Embed the platform’s integrated Dashboards feature within your custom applications. Empower end users to create and configure dashboards through an intuitive interface—all within a fully white-labelled environment that preserves brand consistency and user experience control.

For more information on this topic, see https://developer.davra.com/microservices (opens new window).

Conclusions

Implementing condition monitoring with the Davra Platform empowers organisations to unlock the full potential of condition-based maintenance and predictive maintenance, reducing downtime while maximising efficiency and asset performance. By following the steps outlined above, you can build a scalable, future-ready monitoring system tailored to your needs.

Ready to take the next step? Contact Davra today to explore how our platform can help you design and deploy a condition monitoring solution that delivers measurable value from day one.